EN 1.4581 stainless steel

is an austenitic stainless steel formulated for casting. 1.4581 is the EN

numeric designation for this material. GX5CrNiMoNb19-11-2 is the EN chemical

designation.

|

Designation

|

Standard

|

Chemical

Compositions (%)

|

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

Nb

|

Cu

|

|

1.4581

|

DIN EN 10283: 2010-06

|

ສູງສຸດທີ່ເຄຍ.

|

0.07

|

1.50

|

1.50

|

0.040

|

0.030

|

20.00

|

2.50

|

12.00

|

1.00

|

0.50

|

|

Min.

|

|

|

|

|

|

18.00

|

2.00

|

9.00

|

8X% C

|

|

|

Designation

|

Standard

|

Physical Property

|

|

Rm (MPA)

|

Rp1.0 (MPA)

|

Akv(J)

|

|

1.4581

|

DIN EN 10283: 2010-06

|

ສູງສຸດທີ່ເຄຍ.

|

|

|

|

|

Min.

|

440

|

210

|

40

|

The main property of

1.4581 stainless steel casting, the material of 1.4581 contains niobium (Nb).

Niobium is an effective microalloying element for steel, within which it forms

niobium carbide and niobium nitride. These compounds improve the grain refining,

and retard recrystallization and precipitation hardening. These effects in turn

increase the toughness, strength, formability, and weldability. Within micro

alloyed stainless steels, the niobium content is a small (less than 0.1%) but

important addition to high strength low alloy steels that are widely used

structurally in modern automobiles. Niobium is sometimes used in considerably

higher quantities for highly wear-resistant machine components and knives.

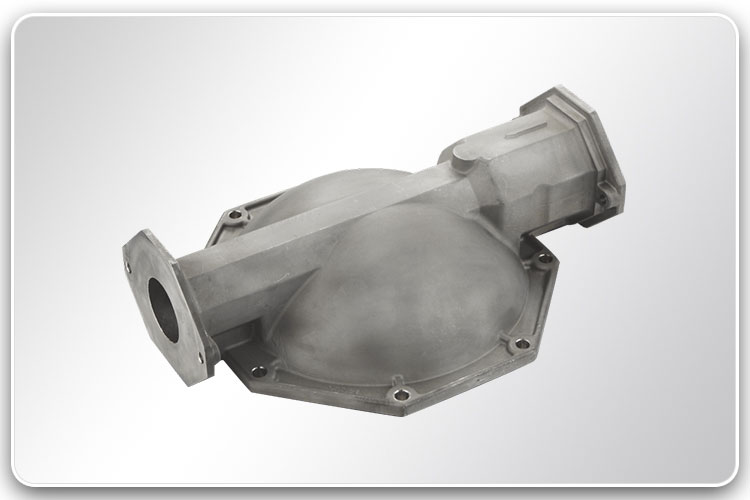

Auwell ເລີ່ມຕົ້ນການຫລໍ່ຫລອມເຫລັກສະແຕນເລດ 1.4581 ຈາກປີ 2017 ສຳ ລັບການຜະລິດເຄື່ອງຈັກ ໜັງ ສືພິມຢູໂຣບທີ່ມີຊື່ສຽງຄືແຜ່ນໃບຄ້າຍຄື rotor. ການຫລໍ່ເຫຼັກສະແຕນເລດ 1.4581, ສ່ວນປະກອບສ່ວນປະກອບຂອງມັນແມ່ນເທົ່າກັບ 316L ໂດຍການເພີ່ມ Nb ຕ່ ຳ ກວ່າ 1% ແຕ່ຕ້ອງມີເນື້ອຫາກາກບອນ 8times (C ‰¤¤ 0.07%), ເຮັດໃຫ້ມັນທົນທານຕໍ່ອາຊິດແຮ່ທາດ.

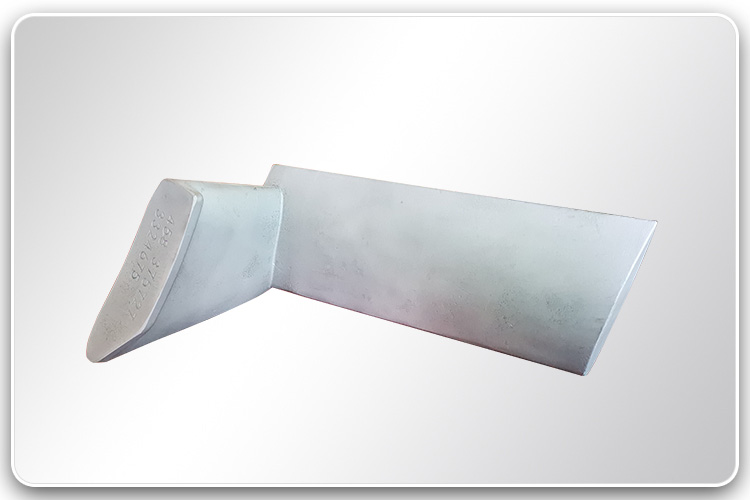

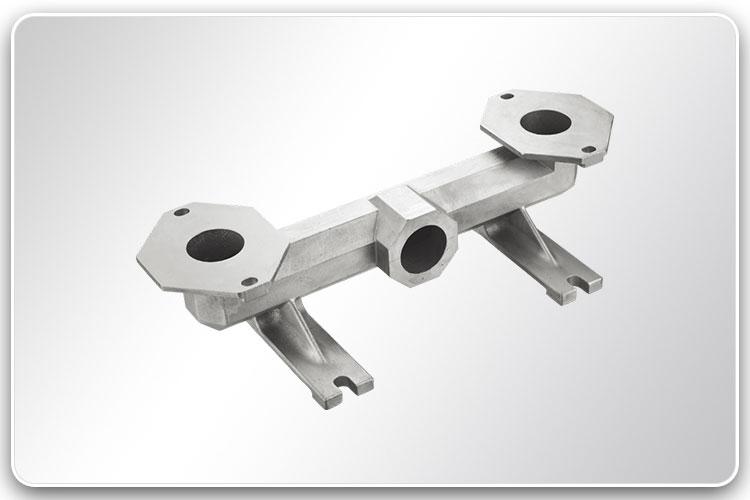

This unique L shape

1.4581 stainless steel casting parts production used to be the big challenge

for us, the different shrinkage rate will easily cause the deformation. Now we

have mature technology in control the product shape the dimensional tolerance.

We provide following

reports to the client upon request for 1.4581 stainless steel casting parts:

-Chemical components

-ໃບຢັ້ງຢືນຊັບສິນທາງກາຍະພາບ

-Hardness report

-ບົດລາຍງານຫຍາບຄາຍ

-Metallographic analysis

report

-ບົດລາຍງານການທົດສອບ radiographic

-Heat treatment report

-ບົດລາຍງານມິຕິ

-3D Scanning Report

ຂໍ້ເສຍປຽບດ້ານການແຂ່ງຂັນ Auwell:

-ປະສົບການທີ່ອຸດົມສົມບູນ

More than 3 years of

experience in 1.4581 stainless steel casting products development and

production, especially to the European markets, with solid understanding of the

material, technical and quality standards.

-Turnaround ໄວ

ໂດຍທົ່ວໄປ, ພວກເຮົາສະ ໜອງ ນໍ້າພາຍໃນ 3 ວັນເຮັດວຽກ. ສົມທົບກັບເຕັກໂນໂລຢີການຜະລິດແລະສິ່ງ ອຳ ນວຍຄວາມສະດວກລ້າສຸດ, Auwell ສາມາດສະ ໜອງ ແບບຢ່າງໄວໃນພຽງ 3 ອາທິດ ສຳ ລັບໂຄງການງ່າຍໆ.

-Comprehensive Solution Provider

Auwell ໃຫ້ບໍລິການທີ່ສົມບູນແບບ ສຳ ລັບຜະລິດຕະພັນຫລໍ່ເຫຼັກສະແຕນເລດ 1.4581 ເລີ່ມອອກແບບ, ຈາກການອອກແບບ, ການພັດທະນາເຄື່ອງມື / ການປັບຕົວ, ການເກັບຕົວຢ່າງ, ການຜະລິດມວນຊົນແລະການສະ ໜັບ ສະ ໜູນ ດ້ານ logistic ແລະຫລັງການຂາຍ.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. Other reports include dimensional reports,

surface treatment thickness, and salt fog test reports, etc. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Flexible Payment Term

ການຈ່າຍເຄື່ອງມື ຈຳ ເປັນຕ້ອງຈ່າຍລ່ວງ ໜ້າ ສຳ ລັບການພັດທະນາຜະລິດຕະພັນຫລໍ່ເຫຼັກກ້າ 1.4581. ສຳ ລັບການຜະລິດຕັ້ງມະຫາຊົນ, ພວກເຮົາສະ ເໜີ ເງື່ອນໄຂການ ຊຳ ລະເງິນທີ່ມີຄວາມຍືດຫຍຸ່ນ, ການປ່ອຍສິນເຊື່ອທີ່ສົມເຫດສົມຜົນຈະຖືກມອບໃຫ້, ລູກຄ້າຈ່າຍພຽງແຕ່ເມື່ອພວກເຂົາພໍໃຈກັບຜະລິດຕະພັນທີ່ພວກເຂົາໄດ້ຮັບ. ສຳ ລັບໂຄງການໄລຍະຍາວ, ພວກເຮົາສະ ເໜີ ການບໍລິການສາງໂທອອກເພື່ອຄວາມຕ້ອງການ fastdelivery.

Hot Tags: ໂຮງງານຜະລິດເຫລັກສະແຕນເລດ 1.4581, ຜູ້ຜະລິດ, ຜູ້ສະ ໜອງ, ໂຮງງານ, ຜະລິດເອງ, ເຮັດຢູ່ໃນປະເທດຈີນ, ຈີນ

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик