Auwell CNC machining parts manufacture equips with conversion lathe, CNC

lathe, 2-axis to 5-axis CNC machining machines, and other relevant machines

including grinding machines, EDM machines, wire cut machines. We can utilise

the most suitable machine for production to reach the desired quality while

being cost-effective.

Auwell is capable in CAM programming for high efficiency and desirable

quality. The Auwell team can design the necessary fixtures and tools for the

milling process and test gauge for CNC machining parts mass production quality

control. CMM is available for sample dimensional inspection. Surface treatments

include grinding, polishing, electrochemical deburring, KTL, powder coating,

painting, zinc plating, nickel plating, chromating, blackening and laser

marking, etc., for aluminum parts, anodizing and silver plating is also

available. PPAP documents are available upon request for our CNC machining

parts.

ວັດສະດຸ ສຳ ລັບຊິ້ນສ່ວນເຄື່ອງຈັກ Auwell CNC ລວມທັງເຫຼັກອ່ອນ, ສະແຕນເລດ, ທອງແດງ, ທອງເຫລືອງ, ອະລູມີນຽມ, ແລະເຫລັກປະສົມ. ດ້ວຍການເອົາໃຈໃສ່ການອົບພະຍົບ, ການຟອກຮ້ອນ, ການສ້າງແບບເຢັນ, ການລົງທືນ, ການຫລໍ່ຫລອມ, ແລະອື່ນໆ.

ຂໍ້ໄດ້ປຽບພາກສ່ວນເຄື່ອງຈັກຂອງເຄື່ອງຈັກ Auwell CNC

-Rich Experience

More than 20 years of

experience in CNC machining parts development and production, especially to the

European and North American markets, with a solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

ໂດຍທົ່ວໄປ, ພວກເຮົາສະ ໜອງ ເຄື່ອງເຈາະ ສຳ ລັບຊິ້ນສ່ວນເຄື່ອງຈັກ CNC ພາຍໃນ 3 ວັນເຮັດວຽກ. ສົມທົບກັບເຕັກໂນໂລຢີແລະສິ່ງ ອຳ ນວຍຄວາມສະດວກທີ່ຜະລິດ ໃໝ່ ລ້າສຸດ, Auwell ສາມາດໃຫ້ prototypesin ໄວພຽງ 2 ອາທິດ ສຳ ລັບໂຄງການງ່າຍໆ.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for CNC machining parts starting from designing, through

prototyping, tooling/fixture development, sampling, mass production, and

logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy for our CNC machining parts starts from material control and is followed

through to final pre-shipment inspection. Material certificates include the

mill certificate, 3rd party chemical components, and mechanical property

reports, as well as RoHS and REACH reports upon request. Other reports include

dimensional reports, surface treatment thickness, and salt fog test reports,

etc. We structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-ໄລຍະການຈ່າຍແບບຍືດຫຍຸ່ນ

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

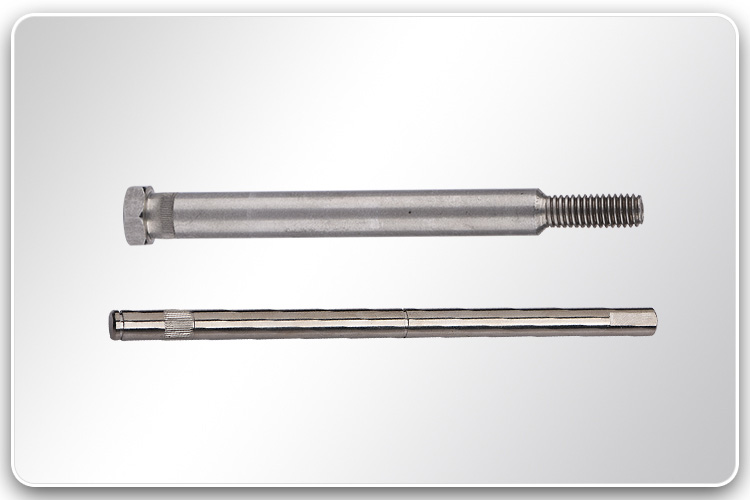

The following catalogues of CNC machining parts are the

ones that Auwell has produced and supplied to our distinguished worldwide

clients. Please click the relevant pictures for details. Please be advised,

most of the products are for demonstration purposes only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик