ລາຍລະອຽດ

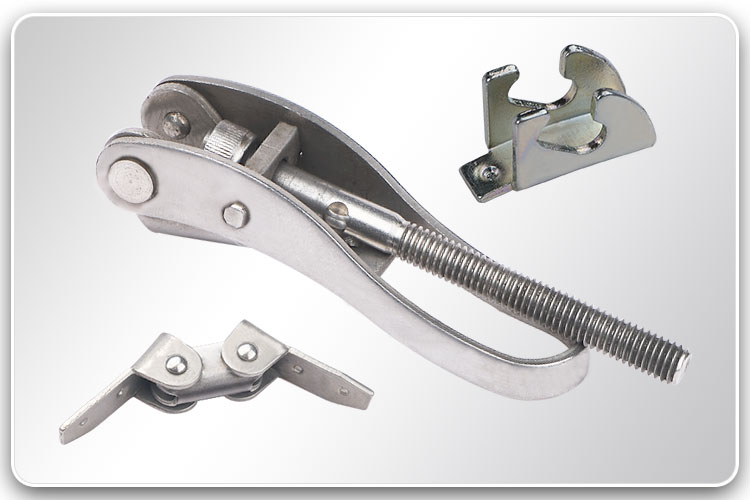

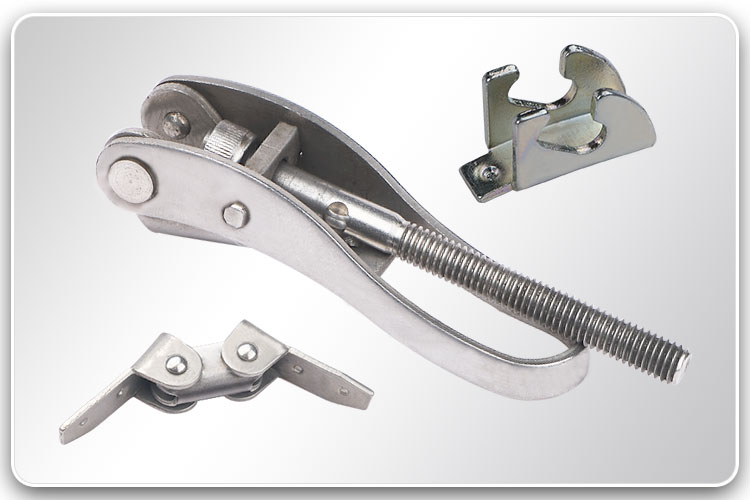

The Saddle for Clamping Rings (stamping part) is the critical component

for clamping ring products. Each clamping ring consists of at least 4 saddle

parts. The Saddle for Clamping Rings is directly assembled with the clamping

ring parts through butt welding followed by hand welding for

reinforcement.

The essential control points for the Saddle for Clamping Rings are the

tolerance for the slots and the height of the butting welding bulges. The slot

contact point with the turning parts arm need to be pressed in, making sure that

the turning parts can rotate freely while being held in place. The definite and

consistent height of the welds is the guarantee for high welding quality.

Auwell ມີປະສົບການຫຼາຍກວ່າ 15 ປີໃນການຜະລິດແລະສະ ໜອງ Saddle ສຳ ລັບຜະລິດຕະພັນ Clamping Rings, ໃນເວລານີ້, 100% ຂອງຜະລິດຕະພັນທີ່ສົ່ງອອກໄປຍັງ Germany ສຳ ລັບລູກຄ້າທີ່ມີກຽດຂອງພວກເຮົາ. ໂດຍມີເຄື່ອງຕາຍທີ່ກ້າວ ໜ້າ, Auwell ສາມາດຜະລິດ Saddle ສຳ ລັບພາກສ່ວນ Clamping Rings ທີ່ມີປະສິດຕິຜົນໃນການບັງຄັບໃຊ້. ການປະທັບຕາແບບກ້າວ ໜ້າ ແມ່ນການຮັບປະກັນຄຸນນະພາບ.

ໂດຍການ ນຳ ໃຊ້ເຕັກໂນໂລຢີແລະການຂຽນໂປແກຼມທີ່ດີທີ່ສຸດ, ຜະລິດຕະພັນກະເປົາຂອງພວກເຮົາໄດ້ຮັບການພິສູດວ່າມີຄຸນນະພາບດີໃນລາຄາທີ່ ເໝາະ ສົມ.

ວິດີໂອຕໍ່ໄປນີ້ສະແດງໃຫ້ເຫັນວິທີການທີ່ເປັນມືອາຊີບຂອງພວກເຮົາໃນການຜະລິດກະເປົາ:

The Saddle for Clamping Rings products displayed are custom made

exclusively for our distinguished clients. We are happy to offer competitive price

to all inquiries from potential clients.

Technical Specifications

-ວັດສະດຸ: ST12, ST37, Q235B, ເຫລໍກສະແຕນເລດ 304, 316L ຫຼືຕາມການຮ້ອງຂໍ

-Saddle thickness: 2.5mm

-Surface: light oil rust

protection

-ຂໍ້ມູນກ່ຽວກັບການຫຸ້ມຫໍ່: ມີຕາມການຮ້ອງຂໍ

ຂໍ້ໄດ້ປຽບ

-Rich Experience

ມີປະສົບການຫຼາຍກວ່າ 15 ປີໃນການຜະລິດກະເປົາໃນການພັດທະນາແລະການຜະລິດແຫວນ, ໂດຍສະເພາະຕະຫຼາດເອີຣົບ. ດ້ວຍຄວາມເຂົ້າໃຈດ້ານວັດຖຸ, ມາດຕະຖານດ້ານເຕັກນິກແລະຄຸນນະພາບທົ່ວໂລກ.

-Fast Turnaround

ໂດຍທົ່ວໄປ, ພວກເຮົາສະ ໜອງ ນໍ້າພາຍໃນ 3 ວັນເຮັດວຽກ. ການປະສົມປະສານກັບເຕັກໂນໂລຢີການຜະລິດແລະສະຖານທີ່ລ້າສຸດ, Auwell ສາມາດສະ ໜອງ ແບບຢ່າງໄວວາ ສຳ ລັບວົງແຫວນຫ້ອຍໃນເວລາພຽງ 3 ອາທິດ ສຳ ລັບຊິ້ນສ່ວນຂອງ saddle.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for saddle for clamping rings projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-ນະໂຍບາຍທີ່ເຂັ້ມແຂງ QC

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Related Products

ຕົວເຊື່ອມຕໍ່ທີ່ລວດໄວສໍາລັບການຍຶດແຫວນ

ຕົວເຊື່ອມຕໍ່ທີ່ລວດໄວສໍາລັບການຍຶດແຫວນ

Turning Parts for Clamping Rings

Turning Parts for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик